5.

Operating your S-4 in the

User Mode

There are times when the material in the Supply Hopper does not lend

itself

very well to the “Automatic” mode of operation. Materials that are

“sticky”

or inconsistent can “fool” the controller in the automatic mode. These

materials usually run better in the “User” mode. When using the

Controller

in this mode, the operator must enter all of the operating parameters

using

the target weight up and down arrow switches.

The

Fill Process

The S-4 Controller in User mode fills a container as follows. It fills

the major portion of the container at a high speed (Bulk Speed) until

it

reaches a certain weight (Bulk Cutoff). It then fills the remainder of

the container at a slower speed (Dribble Speed) until it reaches a

terminal

weight (Dribble Cutoff). The terminal weight is usually a bit less than

the final weight because a small amount of material falls into the

container

after the vibrator motor turns off.

For example, if the operator was filling bags with 5 pounds of rice,

he/she might program the S-4 Controller to fill the first 4.75 pounds

at

a high vibrator motor speed. The Bulk Cutoff would be 4.75 pounds and

the

Bulk Speed might be 50% of full motor speed. The remaining pound of

material

might then get filled at a lower vibrator motor speed. The operator

might

program a Dribble Speed of 20% and a Dribble Cutoff of 4.98 pounds

guessing

that the final 0.02 pounds will fall into the container after the

controller

turns off the vibrator motor.

|

|

The

following is a step-by-step description

of operating the S-3 in User Mode:

- Turn on the

Controller

Every time the controller is turned on using the power switch, the

LCD screen displays a short “splash” screen (fig. 1) that indicates the

model number and revision number. You should see a line like “S4 Rev

1.06”.

In this example, the first part of the message “S4” would tell you that

the controller is setup for the Model S-4 machine. If this first part

shows

“S3”, call Alard Equipment Corp for instructions on changing it to

“S4”.

The “Rev 1.06” part of the message is indicating the software revision

in the controller (1.06 in this example). Write this down so that if

you

need to call Alard Equipment Corp. with a question, they will know what

machine you have.

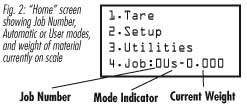

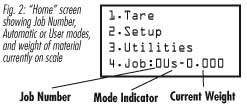

Once the “splash” screen has past, the “Home”

screen (fig. 2) will show

a short menu, a “Job number”, an indication of whether the current job

is “automatic” or “manual”, and the weight indicated by the scale.

The “Job number” is the job currently being used. The controller can

store several jobs that the operator has setup and saved in its

internal

memory and the operator can recall those jobs later on. A Job is a set

of parameters that tell the controller how to fill a particular

container

with a particular amount of material. All jobs are saved when the power

is removed.

There are 2 characters after the job number.

They will either be “Au”

indicating that the currently loaded job is an “automatic” mode job or

“Us” indicating the current job is a “User” mode job. An automatic job

means the controller will constantly adjust the job parameters during

operation

and a user job will use fixed operator supplied parameters and will

make

no adjustments.

The weight of the material currently in the

Scale/Accumulation Hopper

will be shown on the bottom right side of the LCD display. If you

connected

the scale you should be able to make this weight change by pressing on

the Scale/Accumulation Hopper.

|

|

- Load a Job

We will load job number 2 for this example. Load the current job number

2 from the controller’s memory by pressing “Home 2,3” to get to the

load

job screen (fig. 3). You will be asked to enter the job number you want

to load. Press “2” and then “Enter” to load the parameters currently

saved

in job#2. After hitting “Enter” you will be returned to the main

screen.

Notice that the bottom line of the display starts with “Job: 2” (fig.

4).

This is telling you that job number 2 is being used.

|

|

- Setup

Operating Modes

Now we need to tell the controller to use “user” mode for this job.

This forces the controller to use operator supplied parameters while it

is running. Press “Home 2,2” to get to the “Edit Modes” menu (fig. 5).

The first item in this menu should be “Mode”. By pressing the “1” key

you

can toggle the mode from “Auto” to “User”. Toggle the mode to indicate

“User”

While you are in this menu, notice the other

menu items. Press the “2”

key o toggle the “AutoDump” setting to “Off”. Use the “3” key to toggle

the “AutoTare” to “Off”.

Once you have made the above changed to the

Modes, press Home to go

back to the home screen.

|

|

- Set the

Bulk Cutoff Weight

If we are running the job described above we will want to enter the

bulk cutoff weight of 4.75 lbs. Press “Home 2,1” to get to the

parameter

edit list. Press the “1” key to edit the bulk cutoff weight (fig. 6).

If

while entering the parameter you make a mistake, you can press the C/CE

key to clear your entry and reenter the parameter. Enter the desired

bulk

cutoff weight and press enter when you are done. (Your Model S-4 comes

calibrated in pounds. If you wish to change to the metric system, see

the

section on calibration , listed below.) You will be returned to the

parameter

edit list. You can use the arrow keys to view all of these parameters.

Use the “Home” key to return to the main screen.

|

|

- Set the

Bulk Speed

Press “Home 2,1” to get to the parameter edit list if you are not

already

in it. Press the “2” key to edit the bulk speed (fig. 7). If while

entering

the parameter you make a mistake, you can press the C/CE key to clear

your

entry and reenter the parameter. Enter the desired bulk speed and press

enter when you are done. (Both Bulk and dribble speeds are displayed as

a percent of 100%, full speed.) You will be returned to the parameter

edit

list. You can use the arrow keys to view all of these parameters. Use

the

“Home” key to return to the main screen.

|

|

- Set the

Dribble Cutoff Weight

Press “Home 2,1” to get to the parameter edit list if you are not

already

in it. Press the “3” key to edit the dribble cutoff weight (fig 8). If

while entering the parameter you make a mistake, you can press the C/CE

key to clear your entry and reenter the parameter. Enter the desired

dribble

cutoff weight and press enter when you are done. You will be returned

to

the parameter edit list. You can use the arrow keys to view all of

these

parameters. Use the “Home” key to return to the main screen.

|

|

- Set the

Dribble Speed

Press “Home 2,1” to get to the parameter edit list if you are not

already

in it. Press the “4” key to edit the dribble speed (fig. 9). If while

entering

the parameter you make a mistake, you can press the C/CE key to clear

your

entry and reenter the parameter. Enter the desired dribble speed and

press

enter when you are done. You will be returned to the parameter edit

list.

You can use the arrow keys to view all of these parameters. Use the

“Home”

key to return to the main screen.

|

|

- Set the

Target Weight

Press “Home 2,1” to get to the parameter edit list if you are not

already

in it. You can use the up and down arrow keys to view all the

parameters.

Press the “5” key to edit the target weight (fig. 10). If while

entering

the parameter you make a mistake, you can press the C/CE key to clear

your

entry and reenter the parameter. Enter the desired target weight and

press

enter when you are done. You will be returned to the parameter edit

list.

You can use the arrow keys to view all of these parameters. Use the

“Home”

key to return to the main screen.

|

|

- Set the

Drop Gate Open Time

The drop gate open time is the time that the controller leaves the

gate open. This and the drop gate close time can be adjusted to

optimize

cycle time. Press “Home 2,1” to get to the parameter edit list if you

are

not already in it. You can use the up and down arrow keys to view all

the

parameters. Press the “8” key to edit the drop gate open time (fig.

11).

If while entering the parameter you make a mistake, you can press the

C/CE

key to clear your entry and reenter the parameter. Enter the desired

open

time and press enter when you are done. You will be returned to the

parameter

edit list. You can use the arrow keys to view all of these parameters.

Use the “Home” key to return to the main screen.

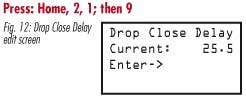

- Set

the Drop Gate Close Time

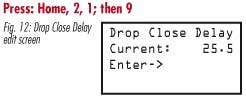

Press “Home 2,1” to get to the parameter edit list if you are not

already

in it. You can use the up and down arrow keys to view all the

parameters.

Press the “9” key to edit the drop gate close time (fig. 12)

|

|

- Tare the

Scale

With nothing on the Scale, press”Home 1” (fig. 13). The display should

read “0.000”. This removes any offset in the scale so that anything you

now put on the scale will be weighed from a value of zero.

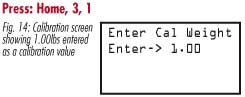

- Check

Calibration of the Scale

Place a known weight on the scale and see if it is accurate. If it

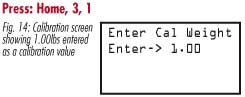

is not, you must “calibrate the scale”. To calibrate the scale, first

tare

the scale (see above), then put an object of known weight on the scale.

Press “Home 3,1” to get to the calibrate screen (fig. 14). You will be

prompted to enter the weight of the object you put on the scale. Enter

the weight of the object and press “Enter”. You will be returned to the

main screen where you should see the correct weight for the object on

the

scale.

|

|

- Adjust the

Supply Hopper Gate

Set the height of the Supply Hopper Gate to something that will

restrict

the material flowing from the Supply Hopper to the Feed Pan so that it

will flow smoothly. You may have to adjust this later on.

- Put

some material in the Hopper

Put your material in the Hopper. It should flow down into the Feed

Pan/Vibrator. You may have to push some material down into the Feed Pan

to get things started.

- Press

the Foot Switch

Press the Foot Switch to start the fill cycle. The “Drop Gate” will

open and close and the vibrator will start. If you have the optional

Feed

Pan Gate, it will open. The Controller will use the supplied parameters

to fill the accumulate hopper. When the accumulator has been filled the

display will indicate the weight of the material in the Accumulation

Hopper.

|

|

- Fine Tuning

Material Flow

If you find the vibrator is running very fast and/or it takes a long

time for the accumulator to fill, you may have the Supply Hopper Gate

too

restrictive for the material in the Supply Hopper. On the other hand,

if

the container fills quickly but is not very accurate, the Supply Hopper

Gate may not be restrictive enough and should be lowered. Generally the

Feed Pan should contain one layer of material when the container is

filling.

For example, if you are filling a container with beans, you should

observe

a continuous flow of beans in the Feed Pan, one bean deep that flows

smoothly

and evenly. If there are gaps or open spots where you can see the

bottom

of the Feed Pan, you should open up the Supply Hopper Gate.

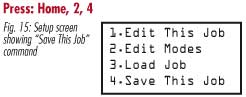

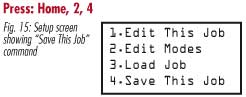

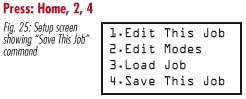

- Save

the Job

You should now save the job so that the next time you turn the machine

on, all the current operating parameters are saved. The S-4 does not

automatically

save jobs. You must save the job. To do this simply press “Home 2,4”

(fig.

15.) This will save all of the current parameters so that the next time

you load this job from the controllers memory, it will operate just as

it did the last time you saved the job.

Back to Top |

|

6.

Operating your S-4 in Automatic

Mode

You are now ready to turn your S-4 on for the first time. We will first

setup a new job filling 0.50 lb containers in “automatic” mode. This

mode

lets the controller adjust itself for optimum performance.

- Turn on the

Controller

Every time the controller is turned on using the power switch, the

LCD screen displays a short “splash” screen (fig. 16) that indicates

the

model number and revision number. You should see a line like “S4 Rev

1.06”.

In this example, the first part of the message “S4” would tell you that

the controller is setup for the Model S-4 machine. If this first part

shows

“S3”, call Alard Equipment Corp for instructions on changing it to

“S4”.

The “Rev 1.06” part of the message is indicating the software revision

in the controller (1.06 in this example). Write this down so that if

you

need to call Alard Equipment Corp. with a question, they will know what

machine you have.

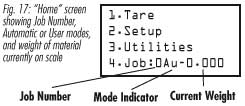

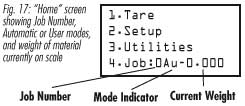

Once the “splash” screen has past, the “Home”

screen (fig. 17) will

show a short menu, a “Job number”, an indication of whether the current

job is “automatic” or “manual”, and the weight indicated by the scale.

The “Job number” is the job currently being used. The controller can

store several jobs that the operator has setup and saved in its

internal

memory and the operator can recall those jobs later on. A Job is a set

of parameters that tell the controller how to fill a particular

container

with a particular amount of material. All jobs are saved when the power

is removed.

There are 2 characters after the job number.

They will either be “Au”

indicating that the currently loaded job is an “automatic” mode job or

“Us” indicating the current job is a “User” mode job. An automatic job

means the controller will constantly adjust the job parameters during

operation

and a user job will use fixed operator supplied parameters and will

make

no adjustments.

The weight of the material currently in the

Scale/Accumulation Hopper

will be shown on the bottom right side of the LCD display. If you

connected

the scale you should be able to make this weight change by pressing on

the Scale/Accumulation Hopper.

|

|

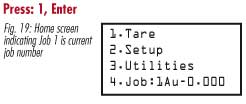

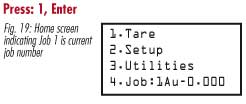

- Load a Job

We will load job number 1 for this example. Load the current job number

1 from the controller’s memory by pressing “Home 2,3” to get to the

load

job screen (fig. 18). You will be asked to enter the job number you

want

to load. Press “1” and then “Enter” to load the parameters currently

saved

in job #1. After hitting “Enter” you will be returned to the Home

screen

(fig. 19). Notice that the bottom line of the display starts with “Job:

1”. This is telling you that job number 1 is being used.

|

|

- Setup

Operating Modes

Now we need to tell the controller to use “automatic mode” for this

job. This allows the controller to try and optimize the running

parameters

while it is running. Press “Home 2,2” to get to the “Edit Modes” menu

(fig.

20). The first item in this menu should be “Mode”. By pressing the “1”

key you can toggle the mode from “Auto” to “User”. Toggle the mode to

indicate

“Auto”

While you are in this menu, notice the other

menu items. Press the “2”

key to toggle the “AutoDump” setting to “Off”. Use the “3” key to

toggle

the “AutoTare” to “Off”.

Once you have made the above changed to the

Modes, press Home to go

back to the home screen.

|

|

- Set Target

Weight

Since we are going to run in “Automatic” mode for this example, the

only parameter we need to adjust is the target weight. Press “Home

2,1,5”

to get to the target weight entry screen (fig. 21). This will prompt

you

for a target weight. Enter “0.5” followed by the “Enter” key. You will

now be returned to the run parameter screen which shows all of the

operating

parameters. Since we will be running in “Automatic” mode you will not

have

to change any of these other items. You can uses the arrow keys to view

all of these parameters. Use the “Home” key to return to the main

screen.

|

|

- Turn On

"Learn" Mode

The last thing we need to do is to tell the controller to do a “Learn”

cycle. The learn cycle is done the first time a new job is run in

automatic

mode so the controller can get a “feel” for how the material flows. The

controller in actually learning on every cycle if it is running in

automatic

mode but for the very first cycle we will tell it to very carefully

learn

the characteristics of the material and how it flows.

To tell the controller to “Learn” on the first

cycle press “Home 3”

to go to the “Utility” screen (fig. 22) and then press “3” to toggle

the

learn mode from “Off” to “On”. Press the “Home” key to return to the

opening

screen.

|

|

- Tare the

Scale

With nothing on the Scale, press “Home 1”. The display should read

“0.000” (fig. 23). This removes any offset in the scale so that

anything

you now put on the scale will be weighed from a value of zero.

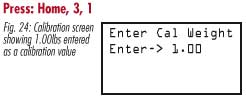

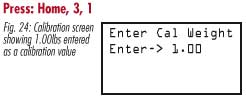

- Check

Calibration of the Scale

Place a known weight on the scale and see if it is accurate. If it

is not, you must “calibrate the scale”. To calibrate the scale, first

tare

the scale (see above), then put an object of known weight on the scale.

Press “Home 3,1” to get to the calibrate screen (fig. 24). You will be

prompted to enter the weight of the object you put on the scale. Enter

the weight of the object and press “Enter”. You will be returned to the

main screen where you should see the correct weight for the object on

the

scale.

|

|

- Adjust the

Supply Hopper Gate

Set the height of the Supply Hopper Gate to something that will

restrict

the material flowing from the Supply Hopper to the Feed Pan so that it

will flow smoothly. You may have to adjust this later on.

- Put

some material in the Hopper

Put your material in the Hopper. It should flow down into the Feed

Pan/Vibrator. You may have to push some material down into the Feed Pan

to get things started.

- Press

the Foot Switch

Press the Foot Switch to start the fill cycle. The “Drop Gate” will

open and close and the vibrator will start. If you have the optional

Feed

Pan Gate, it will open. The Controller will very slowly increase the

power

to the vibrator as it “learns” or tries to judge how to best fill this

container with the given material. During the first cycle the

Controller

operates very slowly while it is trying to figure things out. When the

container has been filled the display will indicate the weight of the

material

in the Accumulation Hopper. You will notice that after the “Learn

Cycle”

each subsequent container will fill a bit more quickly. This is because

the controller is continuously trying to optimize the fill accuracy and

speed.

|

|

- Fine Tuning

Material Flow

If you find the vibrator is running very fast and/or it takes a long

time for the container to fill, you may have the Supply Hopper Gate too

restrictive for the material in the Supply Hopper. On the other hand,

if

the container fills quickly but is not very accurate, the Supply Hopper

Gate may not be restrictive enough and should be lowered. Generally the

Feed Pan should contain one layer of material when the container is

filling.

For example, if you are filling a container with beans, you should

observe

a continuous flow of beans in the Feed Pan, one bean deep that flows

smoothly

and evenly. If there are gaps or open spots where you can see the

bottom

of the Feed Pan, you should open up the Supply Hopper Gate.

- Re-entering

the Learn Cycle

If you make a major adjustment to the Supply Hopper Gate, you should

force the S-4 Controller to start the “Learn Cycle” from the beginning.

To do this, simply press “Home 3,3” to toggle the learn cycle on. You

can

usually make small adjustments to the Supply Hopper Gate without

re-entering

the “Learn Cycle”.

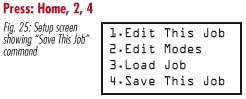

- Save

the Job

After operating several cycle, you should notice that the S-4 has

figured

out how to fill your containers quickly and accurately. You should now

save the job so that the next time you turn the machine on, all the

current

operating parameters are saved. The S-4 does not automatically save

jobs.

You must save the job. To do this simply press “Home 2,4” (fig. 25.)

This

will save all of the current parameters so that the next time you load

this job from the controllers memory, it will operate just as it did

the

last time you saved the job.

Back to Top |

|

7.

Calibrating your S-4

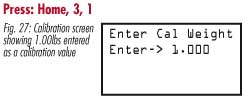

- Tare the

Scale

With nothing on the scale, press the “Home 1” to “tare” or zero out

the scale. After doing this, the display should read “0.000” (fig. 26).

- Put

a known weight on the Scale

Place a known weight on the scale and see if it is accurate. If it

is not, you must “calibrate the scale”. To calibrate the scale, first

tare

the scale (see above), then put an object of known weight on the scale.

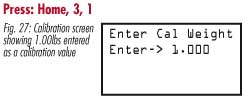

Press “Home 3,1” to get to the calibrate screen. You will be prompted

to

enter the weight of the object you put on the scale (fig. 27). Enter

the

weight of the object and press “Enter”. You will be returned to the

main

screen where you should see the correct weight for the object on the

scale.

*What’s a “known weight”? A known weight can be

any object—a book, a

shoe, your watch—as long as you know how much it weighs. The scale uses

this weight as a base reference for calibration. The accuracy of the

S-3

depends on how accurate your known weight is. If you know the weight of

your known weight within a few thousanths of a pound, the S-3 will be

much

more accurate in its measurements!

- Setting

the Scale to use Metric weight

To set the S-4 to use metric weights, simply use a known weight of

metric value to calibrate the scale. In other words, if you have a

known

weight object that weighs 1.000 kilogram (exactly!) then place that on

the scale during calibration (see section above) and enter “1.000” as

the

calibration value. The weight reading on the scale is now in kilos and

grams

Back to Top |

|